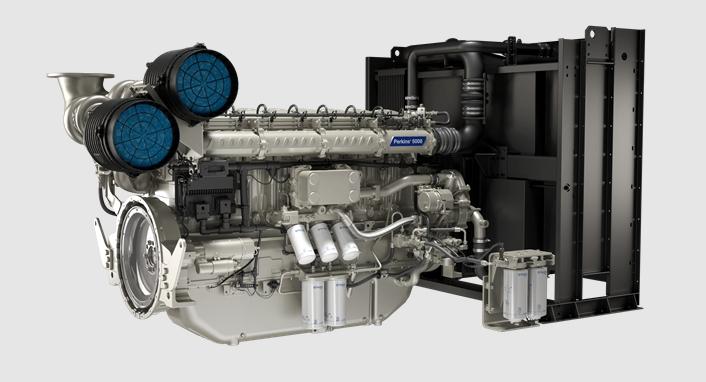

Designed exclusively for the power generation market, the 5000 Series from Perkins ensures a reliable and consistent delivery of prime or standby power, making it ideal for critical applications like data centers and hospitals.

Jaz Gill, Vice President of Perkins Global Sales, Marketing, Service, and Parts, stated:

“The new range has been meticulously crafted to meet our customers’ demands for rapid, dependable, and cost-effective power solutions.”

He further highlighted that in applications where space is limited, like hospitals, the 5000 Series’ high-power density offers a compact design that delivers substantial power within a small footprint.

Perkins offers a diverse range of engines, including inline six- and eight-cylinder, as well as V12 and V16 cylinder configurations, spanning from 750 to 2500 kVA for standby applications and up to 2250 kVA for prime applications. Equipped with newly designed full authority electronic fuel injection, these engines are engineered to ensure high efficiency, minimal fuel consumption, and adherence to global emissions standards. Additionally, subject to meeting Perkins’ specifications, they are capable of running on biodiesel with up to a B20 blend or even on 100% hydrotreated vegetable oil (HVO).

According to Perkins, the 5000 series benefits from optimized turbochargers, ensuring excellent load acceptance that meets ISO 8528-5 G2 and G3 standards, as well as the capability to accept 100% block load in accordance with NFPA standards. These engines have undergone rigorous testing for both performance and durability, accumulating over 10,000 running hours in challenging environments. Additionally, they are engineered to comply with U.S. EPA Tier 2 emissions standards.

The incorporation of redesigned components, such as new piston rings, liner assembly, electronic fuel system, and fuel filters, results in reduced fluid consumption, extended service intervals, and enhanced efficiency, ultimately leading to longer engine life and minimized total cost of operation.

Moreover, Perkins expanding range of connectivity solutions, which can be used as a standalone service or seamlessly integrated with gen-set manufacturers’ offerings, facilitates optimal and sustainable performance.

Through a customizable dashboard, these solutions provide timely insights into various engine data points, including performance, fuel and oil consumption, and other crucial information.