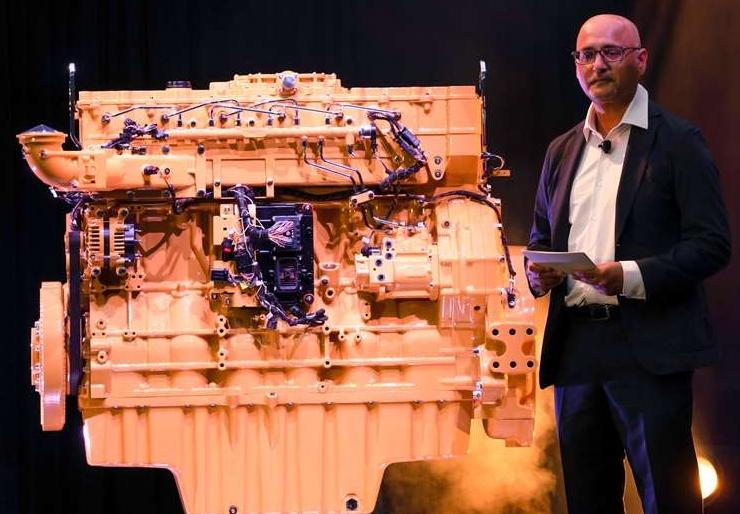

Emerging from over five years of dedicated development, the new CAT engine constitutes a 13-liter platform boasting an impressive power density of up to 52.3 horsepower per liter (40 kW/L). This exceptional attribute empowers the engine to span the output spectrum currently addressed by Caterpillar’s 13, 15, and 18-liter counterparts.

The innovative diesel powerplant is strategically aimed at a diverse array of off-highway machinery, encompassing tasks ranging from rock crushing, screening, and grinding to trenching, agricultural applications including tractors, harvesters, and self-propelled sprayers, as well as wood chipping, material handling operations, and extensive industrial pumping tasks.

“It’s truly a matter of power density and the inherent capabilities of this engine,” explained Mark Stratton, Caterpillar’s Vice President and General Manager overseeing large industrial engines. “This engine’s potential allows us to utilize the platform across sectors where both our competitors and our previous models relied on considerably larger engines. Our existing C13B, C15, and the lower spectrum of the C18 engine series will be effectively replaced by the potency offered by this engine.”

Presenting an inline six-cylinder configuration, the C13D platform will provide a selection of eight power options spanning from 456 to 690 horsepower (340 to 515 kW), accompanied by a peak torque of up to 2360 lb. ft. (3200 Nm). Defined by its bore and stroke measurements of 129.5 x 162.5 mm, this turbocharged and aftercooled engine boasts a total displacement of 12.9 liters. Alongside these specifications, the C13D integrates a host of innovative design attributes, highlighted by:

- An engine block designed with optimized channels throughout the upper and lower water jackets in both the cylinder head and block, ensuring efficient cooling and combustion thermal management, thereby enhancing overall durability.

- Utilization of the latest Caterpillar Zero-static Leak CR900 fuel injectors within a common rail fuel system, which proves to be three times more resilient compared to the existing MEUI-A (Mechanically actuated Electronically controlled Unit Injectors) system. This system is paired with a high-capacity fuel rail capable of handling pressures up to 36,000 psi (250 MPa).

- Inclusion of a novel variable geometry turbocharger to optimize performance.

- A combination of an oil-lubricated fuel transfer pump and high-pressure fuel pump, utilizing pressurized clean oil for effective lubrication of vital components.

- Presenting a fuel filtration module that consolidates the functionality of numerous components into a singular module. It incorporates innovative cartridge filter technology, negating the need for tertiary filters while allowing extended fuel filter change intervals of up to 1000 hours. This leads to cost savings over the engine’s entire lifespan.

- Incorporation of an integrated, filter-free passive crankcase ventilation and breather system, eliminating the requirement for CCV (Crankcase Ventilation) servicing.

Delivering equivalent power and torque in comparison to Caterpillar’s existing 13-liter, 15-liter, and single-turbo 18-liter engine platforms, the C13D platform offers OEMs the chance to downsize their engines. This downsizing presents an avenue for streamlining design, assembly, and supply chain necessities across various applications. Moreover, this consolidation potential can lead to lowered maintenance needs, reduced parts complexities, and minimized technical training requirements, as stated by Caterpillar.

“In our current heavy-duty inline six lineup, comprising the exceptional C13B, the potent 15-liter C15, and the apex of our engine range, the single-turbo C18,” affirmed David Nicoll, Product Line Manager overseeing large industrial engine development and recently appointed President for Caterpillar’s Medium Wheel Products. “The forthcoming C13D is poised to deliver both power and efficiency across this complete lineup, ensuring our customers will benefit from its capabilities in the future.”

“As our customers contemplate their upcoming product development strategies,” Nicoll explained, “they now have the flexibility to incorporate the C13D throughout the power spectrum. Essentially, they can integrate the C13D where they currently utilize the C13B, C15, and the single-turbo C18. This signifies that scenarios where diverse products necessitate distinct engines can now transition to a singular engine across the entire range. This streamlining aids in engineering efforts, inventory management, maintenance, and the post-purchase support that encompasses engine care. This encapsulates the essence of the ‘power of three’ concept.”

However, what the ‘power of three’ does not imply is that Cat engine users will be compelled to relinquish their existing 13, 15, and 18-liter engines in the near future.

“We won’t be enforcing a mandatory shift,” Allen Chen, Product Marketing Manager for Cat’s Industrial Power Systems Division, clarified. “Our intention is that the value proposition will naturally shine through. The C13D boasts superior power, torque, altitude handling, cold start performance, improved fuel efficiency, reduced vibration, and diminished noise – encompassing all the positive attributes associated with an engine.”

“However, embracing it is not obligatory,” Chen clarified. “We acknowledge and respect the significant engineering undertaking required to integrate a new engine into a chassis. Therefore, we are committed to collaborating closely with dealers and OEMs to identify the most opportune moment for transitioning.”

“With that said, it’s important to note that if and when EPA Tier 5, EU Stage 6, or, for instance, China Nonroad 5 regulations are introduced, the existing platforms – namely, the C13B, C15, and C18 – will not obtain certification for the subsequent emissions standard,” he added.

Upon its introduction, the C13D will conform to the emissions requirements of more stringently regulated markets, including EU Stage 5, U.S. EPA Tier 4 final, China Nonroad 4, Korea Stage 5, and Japan 2014, incorporating Cat’s advanced Clean Emissions Module (CEM). Moreover, engines tailored for regions with less stringent regulations will also be available as part of Cat’s offerings.

The Clean Emissions Module (CEM) integrates novel high-flow end caps and an innovative mixer aimed at curbing fluid consumption. The system also features an in-cylinder dosing mechanism and an intake throttle valve that manages thermal processes, eliminating the necessity for the Caterpillar Regeneration System (CRS), resulting in a reduction of overall complexity.

Additionally, the system integrates Caterpillar’s most recent selective catalytic reduction (SCR) technology, which enhances efficiency across varying temperature spans and leads to reduced consumption of diesel exhaust fluid (DEF), as per Cat’s assertions. The CEM bundle also encompasses a more space-efficient design for the diesel oxidation catalyst (DOC) and diesel particulate filter (DPF).

Depending on the specific application requirements, the company has stated that the CEM can be installed either directly on the engine or at a remote location. Caterpillar’s C13D engine platform not only accommodates conventional fuels but also facilitates the utilization of renewable liquid fuels, including 100% HVO, distilled biodiesel (B100), and even biodiesel conforming to the B100 standard. Furthermore, the engine’s foundational architecture is strategically designed to pave the way for future advancements in natural gas and hydrogen fuel compatibility.

“We maintain an unwavering dedication to the diesel platform as a forward-facing foundation since we recognize its indispensability for our customers,” Stratton asserted. “We are wholeheartedly embracing the ongoing energy transition and the escalating requirement for alternative solutions.”

“However, should a diesel engine be the optimal solution,” he continued, “our aim is to offer the finest option available in the market. Moreover, even within internal combustion engines, contemporary alternatives beyond our conventional diesel are emerging, ones that significantly diminish our carbon footprint throughout the operation’s complete lifecycle. Examples of such alternatives include HVO.”

“We anticipate that this will serve as our foundational platform for forthcoming alternative fuels, including options like natural gas and hydrogen,” Stratton remarked. “This is why ensuring the core engine’s accuracy and establishing comprehensive technology integration right from the outset is of paramount importance.”

Caterpillar has disclosed that the C13D has undergone rigorous testing, accumulating over 12,000 hours of both laboratory and preliminary field trials. The inaugural engine is set to be handed over to a customer for evaluation within the upcoming months. Subsequent pilot engines are slated to be dispatched to additional test customers in 2025, paving the way for production initiation in 2026.

Cat all-in on engines

In recent years, much of the discourse has revolved around technologies aiming to supplant internal combustion engines. However, as Caterpillar, the globe’s foremost producer of engines and construction machinery, introduces its latest off-highway diesel innovation, it sends a resounding message that it firmly believes engine technology still possesses substantial vitality.

Describing the unveiling of the new C13D diesel engine at ConExpo as “a significant milestone for Caterpillar,” Jaz Gill, Vice President of Sales, Marketing, Service, and Aftermarket Parts for Caterpillar’s Industrial Power Systems Division, emphasized the accelerating pace of transformative developments. He pointed out that each day brings forth fresh revelations of revolutionary technologies introducing diverse power solutions.

“Whether it’s rechargeable batteries, hybrids, or alternative fuel options like hydrogen, HVO, and fuel cells, we’re well-versed in all of these technologies, and we’re making substantial investments across the board,” he stated. “While these innovative technologies hold promising prospects for the future, it remains undeniable that the established and reliable internal combustion engine has been the cornerstone power source for the majority of job sites worldwide.”

“Hence, as Caterpillar, our commitment remains steadfast towards diesel,” Gill affirmed. “Our investment will persist, as we identify substantial present and forthcoming prospects for internal combustion engines.”

Cat’s battery energy storage technology

Simultaneously with the introduction of an entirely novel engine concept, Caterpillar leveraged the platform of ConExpo-Con/Agg 2023 to emphasize the potential elevation of non-engine technologies, which might hold a more substantial sway in the years to come.

Foremost among these innovations is the Cat Compact ESS, a mobile battery energy storage system (ESS) designed to complement conventional mobile power solutions. This technology was prominently featured within the company’s Sustainability Hub at ConExpo. The recent ESS modules, initially revealed at Bauma in the previous autumn, are specifically tailored for deployments in scenarios such as remote work sites that necessitate prolonged periods of minimal power consumption, encompassing nocturnal loads, continuous low-demand phases, and instances where a noiseless energy supply is imperative.

Offering versatility, two ESS modules are accessible in configurations of both 50 and 60 Hz. The Cat XES60 ESS furnishes an energy storage capacity of up to 56.8 kWh, while the XES120 offers a substantial 127.9 kWh. Both modules facilitate rapid recharging within a mere four hours, integrating advanced lithium-ion chemistry that ensures thermal steadiness, exceptional discharge/recharge efficiency, and an extended cycle lifespan, as highlighted by Caterpillar.

Featuring uncomplicated and direct connections, the ESS modules allow for swift plug-and-play installation and seamless integration with an assortment of energy sources, encompassing diesel, natural gas, and renewable options like portable PV solar arrays or wind power. This seamless integration facilitates prompt and seamless deployment at worksites. These modules adeptly store excess power generated from these sources and promptly release it as required at the worksite.